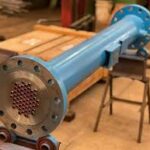

U Tube Heat Exchangers

U-tube Heat Exchangers have U-shaped tubes that allow for thermal expansion and contraction, reducing stress. Efficient for high temperatures and pressures, they are used in power plants, chemical processing, and HVAC systems. The design simplifies cleaning and maintenance, with one end of the tube bundle removable for easy access.

U Tube Heat Exchangers

Key Factors of

- Thermal Expansion Accommodation: The U-tube design allows for thermal expansion and contraction, reducing stress on the tubes and increasing durability.

- Efficient Heat Transfer: Effective in transferring heat between two fluids, often used in high-temperature and high-pressure applications.

- Compact Design: Saves space compared to straight-tube heat exchangers.

- Ease of Maintenance: One end of the tube bundle can be removed, simplifying cleaning and maintenance.

- Versatile Applications: Commonly used in power plants, chemical processing, and HVAC systems.

- Cost-Effective: Generally more economical than some other heat exchanger designs due to their efficiency and ease of maintenance.

U Tube Heat Exchangers

Advantages of

- Accommodates thermal expansion and contraction.

- Compact design saves space.

- Simplifies maintenance with removable tube bundle.

- Suitable for diverse applications.

- Cost-effective and efficient.

- Durable and reliable under high temperatures and pressures.

U Tube Heat Exchangers

Comparision Table

| DRAUGHT TYPE / SHAPE | FLOW TYPE | MATERIAL OF CONSTRUCTION | CAPACITY (TR) | FUNCTION |

|---|---|---|---|---|

| Induced / Rectangular | Counter Flow | Stainless Steel | 20 – 300 | Cooling |

| Forced / Round | Cross Flow | Copper | 10 – 200 | Heating |

| Induced / Square | Parallel Flow | Titanium | 50 – 500 | Condensation |

U Tube Heat Exchangers

Functions of

- Heat Transfer:

- Transfers heat between two fluids efficiently, with one fluid flowing inside the tubes and the other flowing outside the tubes within the shell.

- Temperature Regulation:

- Maintains desired temperatures in various industrial processes by heating or cooling fluids.

- Energy Recovery:

- Recovers waste heat from industrial processes and utilizes it for other applications, improving overall energy efficiency.

- Condensation and Evaporation:

- Facilitates the condensation of vapors and evaporation of liquids in processes like distillation and refrigeration.

Other Heat Exchanger We Manufacture

Shell and Tube Condenser

Shell and Tube Condenser is a type of heat exchanger used to condense steam or vapor into liquid. It consists of a series of tubes enclosed within a cylindrical shell.

Shell and Tube Evaporator

Evaporator is a device used in refrigeration and air conditioning systems to absorb heat from its surroundings and evaporate a refrigerant. It operates by allowing the refrigerant

Shell and Tube After Coolers

Shell and Tube After Coolers are heat exchangers designed to cool compressed air or gases after they have been compressed by a compressor they consist of a bundle of tubes

Shell and Tube Inter Coolers

Shell and Tube Inter Coolers is a type of heat exchanger commonly used in various industrial applications to cool fluids or gases. It consists of a series of tubes (tube bundle)

Shell and Tube Oil Coolers

Shell and Tube Oil Coolers are a type of heat exchanger commonly used in industrial applications to cool oil. These coolers consist of a series of tubes (tube bundle)

Fixed Tube Heat Exchangers

The Fixed Tube Sheet Heat Exchanger has a stationary tube sheet, securing heat exchange tubes for stability and integrity. It’s ideal for industrial applications

Removable Tube Heat Exchanger

Removable Tube Heat Exchanger is a heat exchanger designed with components that can be easily disassembled for maintenance, inspection, and cleaning.

Tube Bundle Heat Exchanger

Tube Bundles are assemblies of multiple tubes, held together by tube sheets at either end. They are primarily used in shell and tube heat exchangers