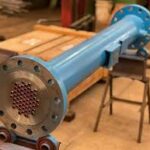

Tube Bundle Heat Exchangers

Tube Bundles are assemblies of multiple tubes, held together by tube sheets at either end. They are primarily used in shell and tube heat exchangers to facilitate heat transfer between two fluids. The tubes can be straight or U-shaped and are typically made from materials with high thermal conductivity, such as stainless steel or copper. The arrangement of the tubes within the bundle can vary to optimize heat exchange efficiency and fluid dynamics.

Tube Bundle Heat Exchangers

Types of

- Straight tube bundle: A straight tube bundle is a type of tube assembly in a heat exchanger where the tubes are arranged in a parallel, straight configuration. Each tube runs the full length of the heat exchanger without bending.

- U-tube bundle: A U-tube bundle in a heat exchanger consists of tubes bent into a U-shape, with both ends of each tube attached to a single tube sheet. This design allows the tubes to expand and contract more freely with temperature changes, reducing thermal stress.

- Floating head tube bundle:A floating head tube bundle in a heat exchanger is a design where one end of the tube bundle is fixed to a stationary tube sheet, while the other end is connected to a tube sheet that can move or “float” within the shell.

Tube Bundle Heat Exchangers

Advantages and Innovation in

- Customizability: Tube bundles can be custom-engineered to meet specific performance requirements, such as maximizing heat transfer efficiency or minimizing pressure drop, by varying tube diameter, length, material, and arrangement.

- Enhanced Turbulence: Incorporation of turbulators or special tube geometries within the bundle can promote turbulence in the fluid flow, thereby improving heat transfer coefficients and overall efficiency.

- Heat Recovery: Tube bundles are integral in heat recovery applications, where they facilitate the transfer of heat from one fluid to another, optimizing energy usage and reducing operating costs.

- Modularity: Their modular design allows for flexibility in system layout and installation, making them suitable for both new constructions and retrofitting into existing systems.

- Multi-Fluid Capability: Tube bundles can handle multiple fluids simultaneously, facilitating complex heat exchange processes such as condensation, evaporation, or phase change applications within the same unit.

- High Temperature and Pressure Resistance: Designed to withstand extreme temperatures and pressures, tube bundles are engineered with materials and construction methods that ensure reliability and safety in demanding industrial environments.

Other Heat Exchanger We Manufacture

Shell and Tube Condenser

Shell and Tube Condenser is a type of heat exchanger used to condense steam or vapor into liquid. It consists of a series of tubes enclosed within a cylindrical shell.

Shell and Tube Evaporator

Evaporator is a device used in refrigeration and air conditioning systems to absorb heat from its surroundings and evaporate a refrigerant. It operates by allowing the refrigerant

Shell and Tube After Coolers

Shell and Tube After Coolers are heat exchangers designed to cool compressed air or gases after they have been compressed by a compressor they consist of a bundle of tubes

Shell and Tube Inter Coolers

Shell and Tube Inter Coolers is a type of heat exchanger commonly used in various industrial applications to cool fluids or gases. It consists of a series of tubes (tube bundle)

Shell and Tube Oil Coolers

Shell and Tube Oil Coolers are a type of heat exchanger commonly used in industrial applications to cool oil. These coolers consist of a series of tubes (tube bundle)

Fixed Tube Heat Exchangers

The Fixed Tube Sheet Heat Exchanger has a stationary tube sheet, securing heat exchange tubes for stability and integrity. It’s ideal for industrial applications

Removable Tube Heat Exchanger

Removable Tube Heat Exchanger is a heat exchanger designed with components that can be easily disassembled for maintenance, inspection, and cleaning.

U-Tube Heat Exchanger

U-tube Heat Exchangers have U-shaped tubes that allow for thermal expansion and contraction, reducing stress. Efficient for high temperatures and pressures,