Structure and Hardware

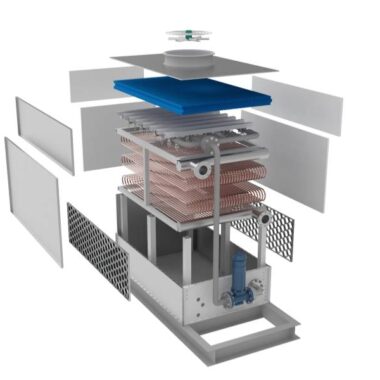

Structure and Hardware of a cooling tower encompass its physical framework and essential components designed to facilitate heat dissipation. This includes the main structural frame made of materials like steel or concrete, the fill media that increases surface area for effective heat exchange, and a distribution system comprising pipes and nozzles to evenly distribute water over the fill. The fan assembly, including blades, motor, and gearbox, circulates air through the tower to aid in cooling. Drift eliminators prevent water loss by capturing droplets in the exhaust air, while a basin collects and recirculates cooled water.

Structure and Hardware

Materials and Components in

- Structural Materials: Steel, reinforced concrete, or fiberglass-reinforced plastic (FRP) for the main framework and support structures, providing strength and durability.

- Fill Media: PVC (polyvinyl chloride) or other plastics designed for enhanced surface area to facilitate efficient heat transfer between water and air.

- Distribution System: PVC or HDPE (high-density polyethylene) pipes, along with various types of nozzles (such as ABS plastic or stainless steel) for water distribution over the fill media.

- Fan Assembly: Aluminum or fiberglass fan blades, electric motors (typically made of aluminum or steel), and gearboxes (often made of cast iron or aluminum alloy) for air circulation and control.

- Drift Eliminators: PVC or FRP panels with engineered profiles to capture water droplets from the exhaust air and prevent their escape, minimizing water loss.

- Basin Construction: Concrete or FRP basins designed to collect and temporarily store cooled water before recirculation or discharge.

Structure and Hardware

Key Components of

- Structural Framework: Typically constructed from steel, reinforced concrete, or fiberglass-reinforced plastic (FRP), the framework provides the necessary support and stability for the entire cooling tower.

- Fill Media: Made from materials like PVC or other plastics, fill media increases the surface area for heat transfer, enhancing the cooling efficiency by maximizing the contact between water and air.

- Water Distribution System: Includes pipes, nozzles, and sprinklers made from PVC, HDPE, or stainless steel, designed to distribute water evenly over the fill media for optimal cooling performance.

- Drift Eliminators: Usually made from PVC or FRP, these components capture water droplets from the exhaust air, reducing water loss and preventing environmental contamination.

- Basin Construction: Basins, made from concrete or FRP, collect and store cooled water for recirculation, ensuring a continuous supply of water for the cooling process.

- Support Structures: Galvanized steel or stainless steel ladders, platforms, and access doors facilitate maintenance and inspection, ensuring safe and efficient operation.

Other Cooling Tower Spares We Manufacture

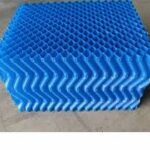

Honeycomb PVC Fills

Honeycomb PVC Fills are a type of fill media used in cooling towers, made from polyvinyl chloride (PVC). They feature a honeycomb-like structure that maximizes the surface area

Drift Eliminators

Drift Eliminators are essential components in cooling towers designed to minimize the loss of water droplets, known as drift, that are carried out of the tower by the exiting airflow.

Axial Fan

Axial Fan is a type of fan that moves air along the axis of its blades. It typically consists of a motor and blades mounted on a shaft within a cylindrical housing. Axial fans are designed

Motors

Motors are specially designed electric motors used to drive fans in cooling towers. They are typically robust and corrosion-resistant, often made of materials like stainless steel

FRP Casing

FRP Casing refers to casings or enclosures made from Fiberglass Reinforced Plastic (FRP). FRP is a composite material consisting of a polymer matrix reinforced with fiberglass fibers.

Distribution Pipes

Distribution Pipes are essential components of infrastructure systems used to convey fluids from a central source to multiple endpoints for consumption or use.

Sprinkler

Sprinkler in cooling towers are mechanical devices designed to evenly distribute water over the fill media inside the tower. They play a crucial role in the cooling process

Nozzles

Nozzles in cooling towers are devices designed to distribute water evenly over the fill material inside the tower. They play a critical role in facilitating efficient heat transfer

Gearbox

Gearbox in a cooling tower is a mechanical component that serves to transmit and control the rotational speed and torque of the fan or other moving parts within the tower.