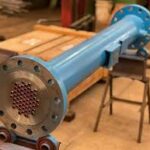

Shell and Tube Inter Coolers

Shell and Tube Inter Coolers is a type of heat exchanger commonly used in various industrial applications to cool fluids or gases. It consists of a series of tubes (tube bundle) enclosed within a cylindrical shell. One fluid flows through the tubes, while another fluid flows over the tubes within the shell, facilitating heat exchange between the two fluids. The design allows efficient heat transfer due to the large surface area provided by the tubes. Shell and tube intercoolers are valued for their robustness, flexibility, and ability to handle high pressures and temperatures.

Shell and Tube Inter Coolers

Operations of

- Tube Side Fluid: The hot fluid flows inside the tubes. It enters the tube side from one end, passes through the length of the tubes, and exits from the other end.

- Shell Side Fluid: The cooling fluid flows over the tubes within the shell. It enters the shell from one end, flows around the tubes, and exits from the other end.

- Conduction: Heat is conducted from the hot fluid to the tube walls.

- Convection: Heat is then transferred from the tube walls to the cooling fluid flowing outside the tubes.

- Counterflow: In this configuration, the two fluids flow in opposite directions. This setup maximizes the temperature difference between the fluids at any point along the heat exchanger, resulting in higher heat transfer efficiency.

Shell and Tube Inter Coolers

Functions of

- Temperature Regulation:

- Maintains the desired temperature of process fluids, ensuring optimal conditions for industrial processes, chemical reactions, and equipment operation.

- Energy Efficiency:

- Improves energy efficiency by recovering waste heat from hot fluids and transferring it to the cooling fluid, which can be repurposed in other parts of the process.

- Process Control:

- Provides stable and consistent temperature control, which is critical for maintaining product quality and process reliability.

- Equipment Protection:

- Prevents overheating of machinery and equipment, thereby avoiding damage and extending their operational life.

Shell and Tube Inter Coolers

Types of

- Fixed Tube Sheet Design: Simple and cost-effective construction.

- U-Tube Design: Allows for differential thermal expansion.

- Floating Tube Bundle: Accommodates thermal expansion without stress.

- Double-Shell and Tube Design: Handles larger temperature differentials efficiently.

- Kettle Reboiler: Ideal for distillation processes with large heat transfer area.

- Hairpin Exchanger: Compact design suitable for space-constrained applications.

- Segmental Baffle Design: Enhances heat transfer by increasing fluid velocity.

Shell and Tube Inter Coolers

Applications of

- Power generation

- Oil refining

- Chemical processing

- HVAC systems

- Food and beverage industry

- Petrochemical industry

- Marine applications

- Automotive industry

- Aerospace and defense

- Pharmaceutical industry

Other Heat Exchanger We Manufacture

Shell and Tube Condenser

Shell and Tube Condenser is a type of heat exchanger used to condense steam or vapor into liquid. It consists of a series of tubes enclosed within a cylindrical shell.

Shell and Tube Evaporator

Evaporator is a device used in refrigeration and air conditioning systems to absorb heat from its surroundings and evaporate a refrigerant. It operates by allowing the refrigerant

Shell and Tube After Coolers

Shell and Tube After Coolers are heat exchangers designed to cool compressed air or gases after they have been compressed by a compressor they consist of a bundle of tubes

Shell and Tube Oil Coolers

Shell and Tube Oil Coolers are a type of heat exchanger commonly used in industrial applications to cool oil. These coolers consist of a series of tubes (tube bundle)

Removable Tube Heat Exchanger

Removable Tube Heat Exchanger is a heat exchanger designed with components that can be easily disassembled for maintenance, inspection, and cleaning.

Fixed Tube Heat Exchangers

The Fixed Tube Sheet Heat Exchanger has a stationary tube sheet, securing heat exchange tubes for stability and integrity. It’s ideal for industrial applications

Tube Bundle Heat Exchanger

Tube Bundles are assemblies of multiple tubes, held together by tube sheets at either end. They are primarily used in shell and tube heat exchangers

U-Tube Heat Exchanger

U-tube Heat Exchangers have U-shaped tubes that allow for thermal expansion and contraction, reducing stress. Efficient for high temperatures and pressures,