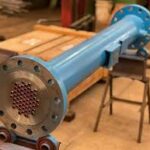

Shell and Tube

Evaporator

Evaporator is a device used in refrigeration and air conditioning systems to absorb heat from its surroundings and evaporate a refrigerant. It operates by allowing the refrigerant, in liquid form, to evaporate into a gas through a series of coils or tubes. This phase change absorbs heat from the surrounding air or fluid, cooling the environment. Evaporators are crucial components in cooling systems, facilitating the transfer of heat and enabling the efficient operation of refrigeration cycles.

Shell and Tube Evaporators

Advantages of

- Efficient Heat Transfer: They facilitate effective heat transfer due to the phase change of the refrigerant from liquid to gas, which absorbs heat from the surroundings.

- Energy Efficiency: Evaporators are typically energy-efficient because they operate by utilizing the latent heat of vaporization, requiring less energy input for cooling.

- Compact Design: They can be designed in compact configurations, making them suitable for various applications where space is limited.

- Versatility: Evaporators are used in a wide range of applications, including refrigeration, air conditioning, and industrial processes, due to their ability to cool liquids and gases efficiently.

- Lower Operating Costs: Compared to other cooling methods, evaporators often have lower operating costs, especially in terms of energy consumption and maintenance.

- Environmental Friendliness: Many evaporators use refrigerants that are less harmful to the environment, contributing to sustainability efforts.

Shell and Tube Evaporators

Roles

- Heat Absorption: The evaporator absorbs heat from the chilled water or other fluid circulating through it.

- Phase Change: It facilitates the phase change of the refrigerant from liquid to vapor as it absorbs heat from the chilled fluid.

- Cooling Effect: By removing heat from the chilled fluid, the evaporator lowers its temperature, providing chilled water or air for cooling applications.

- Efficient Operation: Evaporators ensure that the refrigerant absorbs heat efficiently, enabling the chiller to maintain the desired temperature in the cooling loop.

- Temperature Control: They play a crucial role in controlling and maintaining the temperature of the chilled water or air output from the chiller.

- Cycle Completion: The evaporator completes the refrigeration cycle by releasing cooled refrigerant back to the compressor to continue the cooling process.

Other Heat Exchanger We Manufacture

Shell and Tube Condenser

Shell and Tube Condenser is a type of heat exchanger used to condense steam or vapor into liquid. It consists of a series of tubes enclosed within a cylindrical shell.

Shell and Tube After Coolers

Shell and Tube After Coolers are heat exchangers designed to cool compressed air or gases after they have been compressed by a compressor they consist of a bundle of tubes

Shell and Tube Inter Coolers

Shell and Tube Inter Coolers is a type of heat exchanger commonly used in various industrial applications to cool fluids or gases. It consists of a series of tubes (tube bundle)

Shell and Tube Oil Coolers

Shell and Tube Oil Coolers are a type of heat exchanger commonly used in industrial applications to cool oil. These coolers consist of a series of tubes (tube bundle)

Removable Tube Heat Exchanger

Removable Tube Heat Exchanger is a heat exchanger designed with components that can be easily disassembled for maintenance, inspection, and cleaning.

Fixed Tube Heat Exchangers

The Fixed Tube Sheet Heat Exchanger has a stationary tube sheet, securing heat exchange tubes for stability and integrity. It’s ideal for industrial applications

Tube Bundle Heat Exchanger

Tube Bundles are assemblies of multiple tubes, held together by tube sheets at either end. They are primarily used in shell and tube heat exchangers

U-Tube Heat Exchanger

U-tube Heat Exchangers have U-shaped tubes that allow for thermal expansion and contraction, reducing stress. Efficient for high temperatures and pressures,