Rice Mill Heat Exchanger

Rice Mill Heat Exchanger is a device used to regulate and control the temperature during various stages of rice milling, such as drying, parboiling, and cooling. By efficiently managing heat transfer, it helps maintain the quality of the rice, enhances energy efficiency, and reduces operational costs. These heat exchangers can use air, water, or other fluids to transfer heat, ensuring optimal processing conditions and consistent product quality in rice milling operations.

Rice Mill Heat Exchanger

Future Trends with

- Nanotechnology: Use of nanomaterials to enhance thermal conductivity and corrosion resistance, leading to more efficient and durable heat exchangers.

- Composite Materials: Development of lightweight, high-strength composites that can withstand high temperatures and aggressive environments.

- Heat Recovery Systems: Integration of systems that recover and reuse waste heat, significantly improving overall energy efficiency.

- Optimized Designs: Continuous innovation in design to minimize energy losses and maximize heat transfer efficiency.

- Eco-Friendly Refrigerants: Adoption of environmentally friendly refrigerants and working fluids to reduce greenhouse gas emissions.

- Sustainable Manufacturing: Emphasis on sustainable manufacturing processes and materials that minimize environmental impact

- Self-Cleaning Technologies: Development of self-cleaning mechanisms that reduce fouling and maintenance requirements, extending the lifespan of heat exchangers.

- Durable Coatings: Use of advanced coatings that protect against corrosion, wear, and biofouling, enhancing the longevity and reliability of heat exchangers.

Rice Mill Heat Exchanger

Material and Components of

| Component | Material | Description |

|---|---|---|

| Heat Exchanger Tubes | Stainless Steel, Copper | Tubes where the heat exchange takes place, offering corrosion resistance and efficient heat transfer. |

| Fins | Aluminum, Copper | Attached to the tubes to increase surface area for better heat transfer. |

| Shell | Carbon Steel, Stainless Steel | Encloses the tube bundle and contains the fluids. |

| Baffles | Stainless Steel, Carbon Steel | Directs the flow of fluids to enhance heat transfer efficiency. |

| Fans | Aluminum, Steel | Used in air-cooled systems to blow air over the heat exchanger. |

| Pumps | Cast Iron, Stainless Steel | Circulates fluids through the heat exchanger system. |

| Gaskets | Rubber, PTFE | Seals to prevent leaks between different sections of the heat exchanger. |

Rice Mill Heat Exchanger

Innovation and Energy Efficiency

- Microchannel Heat Exchangers: Use of microchannel technology increases the surface area for heat transfer within a compact design, leading to improved efficiency and reduced energy consumption.

- Enhanced Fin Designs: Innovations in fin geometry, such as louvered or wavy fins, enhance heat transfer by increasing turbulence and surface area.

- Nanomaterials: Incorporation of nanomaterials that offer superior thermal conductivity and corrosion resistance, resulting in better heat exchange and longer service life.

- Composite Materials: Development of lightweight, high-strength composite materials that improve thermal performance while reducing overall weight.

- Solar-Assisted Heat Exchangers: Integration of solar thermal energy to preheat fluids, reducing the load on traditional heating systems and cutting energy costs.

- Hybrid Systems: Combining different energy sources, such as solar and waste heat recovery, to maximize energy efficiency and reduce reliance on non-renewable energy.

- Low Emission Refrigerants: Use of environmentally friendly refrigerants and working fluids that reduce greenhouse gas emissions and improve energy efficiency.

- Green Manufacturing: Adoption of sustainable manufacturing practices that reduce the environmental footprint of heat exchanger production.

Other Finned Tube Heat Exchanger We Manufacture

Chilled Water Finned Tube Coils

Chilled Water Finned Tube Coils are components used in HVAC systems for cooling. They consist of a series of tubes with external fins that increase surface area for heat transfer.

Air Handling Unit

Air Handling Unit (AHU) coil is a vital component in HVAC systems, designed to heat or cool air. It comprises tubes through which refrigerant or water circulates and fins that increase

Fin Tube Evaporator Coil

Fin Tube Evaporator coil is a heat exchanger used in air conditioning and refrigeration systems. It consists of copper or aluminum tubes with aluminum fins attached to them.

Fan Coil Unit

Fan Coil Unit (FCU) is a device used in HVAC systems to control the temperature and airflow in a space. It typically consists of a heat exchanger (coil) connected to a fan

Hot Water Steam Coils

Hot Water Steam Coils are heat exchangers used in HVAC systems to transfer heat from hot water or steam to air. They consist of tubes, usually made of copper or steel,

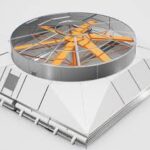

Air Cooled Heat Exchanger

Air Cooled Heat Exchangers (ACHEs) are devices that transfer heat from a fluid (liquid or gas) to the surrounding air. They use finned tubes to increase the surface area for heat transfer

Air Blast Oil Cooler

Air Blast Oil Cooler is a heat exchanger used to cool hydraulic oil, lubricating oil, or other fluids in industrial machinery and automotive applications.

Foundry Sand Cooler

Foundry Sand Cooler is a piece of equipment used in foundries to cool hot sand after it has been used in the casting process. The cooling process is essential to prepare the sand

Aluminum Finned Water Tube Coils

Aluminum Finned Water Tube Coils are heat exchangers used in HVAC systems to transfer heat between air and water. They consist of tubes, typically made of copper or another material