RCC Cooling Tower

RCC Cooling Towers are large, durable structures used in industrial and commercial facilities to dissipate excess heat generated by various processes. These cooling towers are constructed using reinforced cement concrete, which combines the tensile strength of steel with the compressive strength of concrete, resulting in a sturdy and long-lasting construction.

RCC Cooling Tower

Materials of

- Concrete: RCC cooling towers primarily use high-quality concrete, typically with a minimum specified compressive strength ranging from 20 to 40 MPa. This concrete is reinforced with steel bars (rebars) to enhance its tensile strength and resistance to cracking under varying loads and environmental conditions.

- Steel Reinforcement: The steel reinforcement bars (rebars) used in RCC cooling towers are crucial for providing tensile strength and preventing the concrete from cracking due to thermal stresses, wind loads, and seismic forces. Proper detailing and placement of rebars are essential to ensuring structural integrity.

- Waterproofing and Corrosion Protection: Considering the tower’s exposure to water and potentially corrosive environments (such as marine or industrial areas), effective waterproofing measures and corrosion-resistant materials are employed. This includes using additives in concrete, coatings, or liners to protect against deterioration over time.

RCC Cooling Tower

Strength of

- Structural Design: The design of RCC cooling towers involves calculating loads such as dead loads (weight of the structure itself), live loads (operational loads including wind and maintenance loads), and environmental loads (seismic, thermal expansion). The materials’ strength must meet or exceed these demands to ensure safety and longevity.

- Load-bearing Capacity: The compressive strength of concrete and the tensile strength of reinforcement steel are critical in determining the load-bearing capacity of the cooling tower. Engineers carefully calculate and verify these strengths to ensure that the structure can support the anticipated loads throughout its service life.

- Durability: RCC cooling towers are exposed to harsh environmental conditions, including temperature variations and moisture. The materials selected must exhibit durability characteristics, such as resistance to cracking, freeze-thaw cycles, chemical attack, and abrasion, to maintain structural integrity over decades.

RCC Cooling Tower

Parts and Components of

Fan Blades: These are the blades or impellers responsible for generating airflow. They are designed to move large volumes of air efficiently while minimizing power consumption and noise.

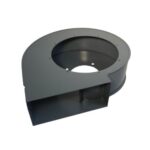

Motor Housing: Encloses and protects the internal components of the motor, providing structural support and heat dissipation.

Fan Housing: The fan housing encloses the blades and motor, directing airflow and providing structural support. It’s often designed to minimize aerodynamic resistance and optimize airflow efficiency.

Stator: The stationary part of the motor that contains the coi ls wound around an iron core. It creates a magnetic field when energized.

Drive System: The drive system includes components such as belts, pulleys, or direct-drive arrangements that transmit power from the motor to the fan blades. Belt-driven systems allow for speed adjustments and maintenance flexibility.

Rotor: The rotating part of the motor, usually consisting of a shaft and conductive windings. It interacts with the stator’s magnetic field to generate rotational motion.

Guard or Safety Grill: This is a protective grill or cover around the fan blades to prevent accidental contact, ensuring safety during operation and maintenance.

Bearings: Bearings support the rotor shaft, allowing smooth rotation with minimal friction. They are essential for the motor’s longevity and efficiency.

Cooling Fan: In some designs, an additional small fan may be attached to the motor shaft to provide cooling air, especially in enclosed motor housings.

Terminal Box: This box houses electrical connections and terminals for power supply and motor control.

Other Cooling Towers We Manufacturer

Square Type Cooling Tower

Square Type Cooling Tower functions on the principle of induced draft counter flow operation. The fan generates vertical air movement that flows upwards on the tower and across the fills, opposing the water flow.

Round Type Cooling Tower

The Round Type Cooling Tower, constructed from FRP, boasts resistance to corrosion, resilience against extreme vibrations, and the ability to withstand high wind loads. Its design emphasizes efficiency

Wooden Cooling Tower

Wooden Cooling Tower are designed to handle water with high levels of dissolved solids (TDS). Hot water from the source is sprayed over special nozzles in a collection basin

Closed Circuit Cooling Tower

Closed Circuit Cooling Tower is a type of heat exchanger that combines the functions of a cooling tower and a heat exchanger in a single unit.

Cross Flow Cooling Tower

Cross flow cooling towers is a cooling system where air flows horizontally through the tower while water flows vertically downward.

Dry Cooling Tower

Dry Cooling Towers is a type of cooling system used in industrial and power generation processes to remove excess heat

Evaporative Cooling Tower

Evaporative cooling tower are devices used to remove excess heat from industrial processes, power plants, and HVAC systems

Natural Draft Cooling Tower

Natural draft cooling towers are a type of cooling tower that uses the natural convection of air to cool water.