Introduction

Laminar flow optimization is a fluid dynamic condition characterized by smooth, orderly movement of fluid particles in parallel layers, with little or no mixing between them. This contrasts with turbulent flow, where chaotic fluid motion leads to mixing and eddies. Achieving and maintaining laminar flow is essential in many industries and scientific applications, as it can lead to more efficient operations, better control over processes, and higher quality end products. Laminar flow optimization refers to the design and management of systems that aim to sustain this stable flow pattern, optimizing factors such as fluid velocity, pipe design, and temperature control to ensure minimal disruption or resistance. In practical terms, laminar flow optimization is vital in applications such as heat exchangers, chemical reactors, and fluid delivery systems. For example, in heat exchangers, laminar flow helps maintain efficient heat transfer, reducing the energy required to regulate temperatures. In medical or pharmaceutical industries, where precision in fluid handling is critical, optimized laminar flow ensures accurate dosing and minimizes the risk of contamination.

Importance in Industrial Applications

Laminar flow optimization is critical in industries such as chemical processing, pharmaceuticals, and microelectronics, where precise control over fluid movement and heat transfer is essential. Maintaining laminar flow can reduce energy consumption, minimize wear and tear on equipment, and improve the quality of end products by ensuring smooth processes. In heat exchangers, for instance, optimized laminar flow can enhance the thermal efficiency by providing uniform heat distribution and minimizing temperature gradients.

Enhanced Heat Transfer

In many systems, maintaining laminar flow can improve the heat transfer coefficient, especially in situations where heat needs to be transferred efficiently between fluids. Optimizing laminar flow helps avoid the formation of boundary layers that can act as thermal resistances. This results in more effective thermal regulation and faster heat exchange between the fluid and surrounding surfaces.

Flow Rate Control

In processes requiring precise control of fluid delivery, such as in dosing applications or fuel injection systems, laminar flow is necessary to ensure accuracy. By optimizing the flow rate and maintaining a steady, non-turbulent flow, industries can achieve better precision in fluid handling, leading to improved performance and reduced errors in product manufacturing.

Reduced Pressure Drop

Laminar flow optimization helps in reducing pressure drop across pipes or channels. In turbulent flows, friction and chaotic movements of the fluid increase energy losses, but with laminar flow, the frictional resistance is lower. By maintaining laminar flow, energy consumption can be minimized, and pumping power can be optimized, leading to more energy-efficient systems.

Low Turbulence and Minimal Vibration

One of the defining benefits of laminar flow optimization is the reduction in turbulence, which can create noise and vibrations in piping and machinery. These vibrations can be detrimental to sensitive equipment and may cause mechanical failure or operational instability. Optimizing laminar flow ensures smooth, stable movement, reducing such risks.

Achieving Laminar Flow in Real-World Systems

In practical applications, achieving and maintaining laminar flow requires careful attention to the design of pipes, channels, and fluid dynamics. Factors such as fluid viscosity, pipe diameter, flow velocity, and surface roughness all play a significant role. To achieve laminar flow, flow rates should be kept within certain limits, and the system’s design should minimize sharp bends or sudden changes in direction that could induce turbulence. Additionally, using fluids with higher viscosity can help stabilize the flow, making laminar conditions easier to maintain.

Optimizing Laminar Flow in Microfluidic Devices

In microfluidic systems, laminar flow optimization is especially critical. These systems, used in applications like medical diagnostics, chemical analysis, and drug delivery, rely on highly controlled fluid movement at very small scales. To achieve the necessary precision and accuracy in such systems, laminar flow must be maintained at all times, which requires careful design and operation of the microchannels involved.

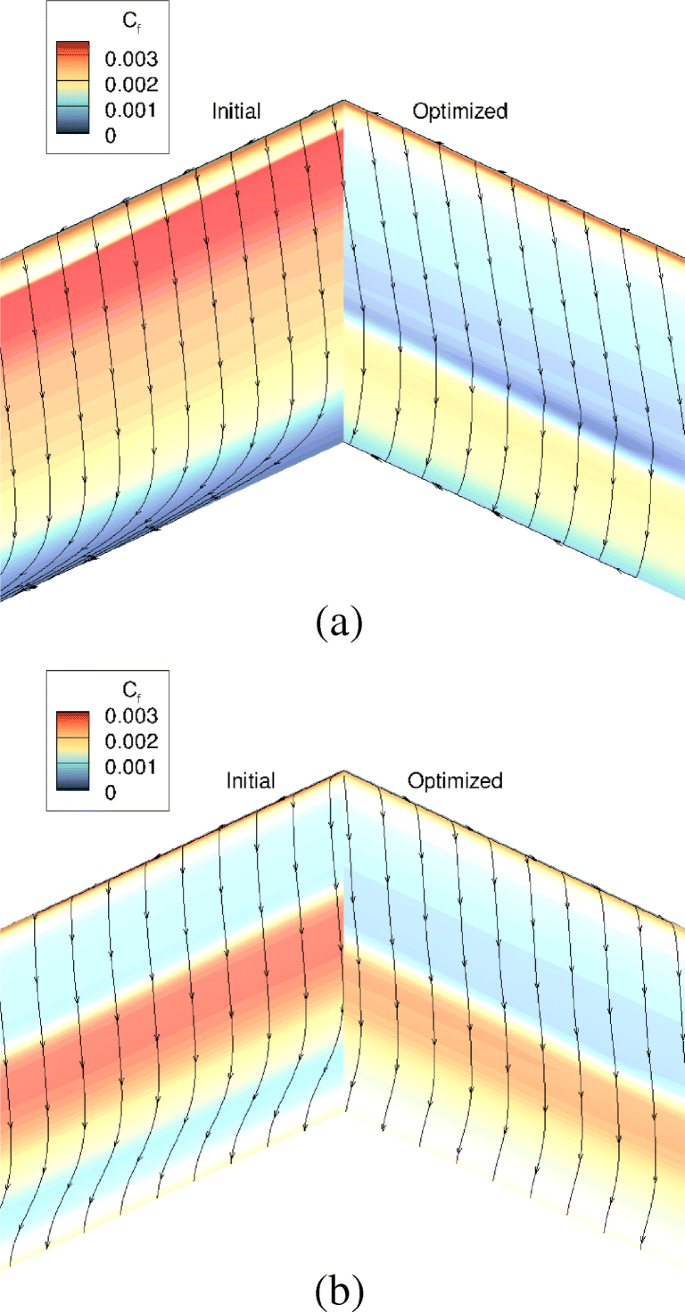

Computational Fluid Dynamics (CFD) for Optimization

Advanced computational techniques like CFD (Computational Fluid Dynamics) have become essential in optimizing laminar flow. CFD simulations can predict how fluid behaves in a system under various conditions, allowing engineers to design components that support smooth, laminar flow. This predictive capability helps optimize efficiency, reduce costs, and troubleshoot potential issues before they arise.

Conclusion

Laminar flow optimizing is a pivotal strategy for improving the performance, efficiency, and sustainability of fluid systems across multiple industries. By focusing on reducing turbulence, minimizing energy losses, and enhancing the precision of fluid delivery, laminar flow optimization offers a range of advantages, from reduced operational costs to improved product quality. The careful management of factors like flow rate, system design, and fluid properties can help ensure that laminar conditions are maintained, which in turn enhances the overall functionality of the system. Furthermore, with the help of modern tools such as Computational Fluid Dynamics (CFD), engineers can predict and fine-tune fluid behavior, allowing for the creation of highly efficient systems that operate at their peak potential. As industries continue to prioritize sustainability, cost-effectiveness, and precision, the optimization of laminar flow will remain a key focus, contributing to more efficient systems and processes.