Introduction

Hydrogen Fuel Cells Cooling have emerged as a promising alternative to traditional fossil fuel-based power systems. These fuel cells generate electricity through an electrochemical reaction between hydrogen and oxygen, producing only water and heat as byproducts. While this process is highly efficient and environmentally friendly, it also generates a substantial amount of waste heat, which, if not effectively managed, can reduce efficiency and compromise the performance of fuel cell systems. To address this challenge, heat exchangers play a crucial role in hydrogen fuel cell cooling by efficiently transferring excess heat away from the system and maintaining the optimal operating temperature. Proper thermal management is essential to ensure maximum efficiency, system reliability, and extended operational lifespan of fuel cells. Heat exchangers are widely used in hydrogen-powered vehicles, industrial power systems, aerospace applications, and stationary fuel cell power plants, where efficient cooling is a critical requirement. With advancements in heat exchanger technology, such as microchannel designs, lightweight materials, and AI-driven cooling systems, hydrogen fuel cell cooling is becoming more efficient and reliable. This article explores how heat exchangers are used in hydrogen fuel cell cooling, their benefits, key factors, and emerging innovations shaping the future of this technology.

Key Factors in Hydrogen Fuel Cell Cooling

Efficient Thermal Regulation

- Hydrogen fuel cells operate optimally within a specific temperature range. If the temperature exceeds this range, it can lead to performance loss, component degradation, and reduced electrical output.

- Heat exchangers remove excess heat from the fuel cell system and ensure consistent and stable thermal conditions, allowing the electrochemical process to function efficiently.

- Maintaining the right temperature also prevents water management issues in fuel cells, such as water condensation that can block airflow and affect power generation.

Selection of Cooling Medium

- Liquid Cooling: Most hydrogen fuel cells use liquid coolants (such as water-glycol mixtures) due to their high heat absorption capacity. These coolants circulate through heat exchangers, transferring heat away from the system.

- Air Cooling: Some low-power fuel cells, such as those used in portable electronics and drones, rely on air-cooled heat exchangers to dissipate heat through convection. These are simpler but less efficient than liquid cooling.

- Hybrid Cooling Systems: Some applications combine liquid and air cooling for better performance, especially in large-scale power plants or heavy-duty vehicles.

Compact and Lightweight Designs

- Fuel cell-powered applications, such as automobiles, trucks, and aerospace systems, require heat exchangers that are small, lightweight, and highly efficient.

- Compact designs maximize cooling efficiency while minimizing weight and space requirements, making them ideal for transportation and mobile energy solutions.

- Advanced microchannel heat exchangers offer high heat transfer rates in a compact footprint, ensuring optimal cooling without adding unnecessary bulk.

Corrosion Resistance and Material Selection

- The heat exchangers used in hydrogen fuel cell cooling must be made from corrosion-resistant materials to withstand exposure to hydrogen, coolants, and environmental conditions.

- Common materials include:

- Stainless Steel: Highly durable and resistant to corrosion.

- Aluminum: Lightweight with good thermal conductivity.

- Titanium: Excellent resistance to corrosion, particularly in marine and aerospace applications.

- Choosing the right material extends the lifespan of the heat exchanger and ensures long-term reliability in fuel cell systems.

Waste Heat Recovery for Efficiency

- Hydrogen fuel cells generate large amounts of waste heat during operation. If this heat is not recovered, it is lost, reducing overall system efficiency.

- Heat exchangers capture this waste heat and redirect it for useful applications such as:

- Cabin heating in fuel cell vehicles

- Pre-heating industrial processes

- Supplying heat for district heating systems

- Utilizing waste heat increases overall energy efficiency and reduces the need for additional heating sources, making fuel cells more sustainable.

Types of Heat Exchangers Used in Hydrogen Fuel Cell Cooling

Plate Heat Exchangers

- Consist of thin metal plates stacked together, allowing efficient heat transfer between fluids.

- Provide high thermal efficiency and compact size, making them ideal for hydrogen fuel cell vehicles and portable systems.

- Designed for quick heat dissipation and easy maintenance, allowing for cost-effective cooling solutions.

Microchannel Heat Exchangers

- Feature narrow channels for coolant flow, increasing heat transfer efficiency while minimizing space requirements.

- Commonly used in fuel cell cars, drones, and high-performance electronics where compact cooling solutions are needed.

- Offer lightweight and energy-efficient cooling, improving overall fuel cell performance.

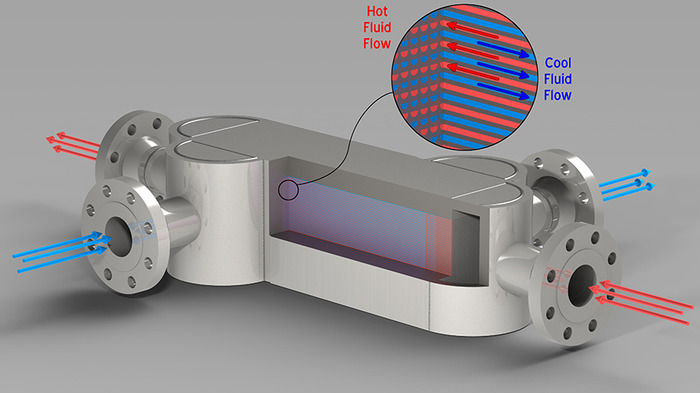

Shell-and-Tube Heat Exchangers

- Consist of multiple tubes enclosed within a larger shell, with coolant flowing through the tubes and absorbing heat from the surrounding fuel cell components.

- Used in large-scale hydrogen power plants and industrial fuel cell systems due to their durability and high heat transfer capacity.

- Provide easy cleaning and maintenance, making them a reliable option for long-term applications.

Air-Cooled Heat Exchangers

- Utilize fans and finned surfaces to increase heat dissipation through airflow.

- Common in low-power applications or areas where liquid cooling is impractical.

- Offer cost-effective and simple cooling solutions, although they are less efficient than liquid-based systems.

Benefits of Heat Exchangers in Hydrogen Fuel Cell Cooling

- Prevents Overheating – Maintains optimal temperature control, preventing damage to fuel cell components.

- Improves Fuel Cell Efficiency – Ensures maximum energy conversion by keeping the reaction temperature stable.

- Extends Component Life – Reduces thermal stress on fuel cells, increasing their durability and lifespan.

- Supports Energy Recovery – Captures waste heat for secondary applications, improving overall energy utilization.

- Enhances System Reliability – Provides consistent cooling performance, ensuring fuel cell reliability in various applications.

- Enables Compact System Design – Modern heat exchangers are small and lightweight, allowing seamless integration into hydrogen-powered vehicles and industrial systems.

Future Trends and Innovations in Hydrogen Fuel Cell Cooling

Advanced Nanomaterials for Heat Exchangers

- Graphene-coated heat exchangers improve thermal conductivity and corrosion resistance.

- Carbon nanotube-based designs enhance heat transfer efficiency in compact systems.

Integration with Smart Thermal Management Systems

- AI-driven cooling systems optimize heat exchanger performance based on real-time temperature monitoring.

- Active thermal control strategies adjust cooling capacity dynamically based on load demand.

Hybrid Cooling Solutions

- Combining liquid and air cooling improves efficiency in high-power applications.

- Phase-change materials (PCMs) absorb and store excess heat, offering passive cooling solutions.

Lightweight and High-Performance Materials

- Titanium and aluminum alloys reduce weight while maintaining high durability.

- 3D-printed heat exchangers enable customized designs for better heat dissipation.

Development of Next-Generation Coolants

- Non-toxic and eco-friendly coolants with higher thermal capacity improve fuel cell efficiency.

- Cryogenic cooling for ultra-efficient fuel cell applications in aerospace and space missions.

Conclusion

Hydrogen Fuel Cells Cooling playing a vital role in maintaining temperature stability, efficiency, and durability. By effectively removing excess heat, they prevent performance degradation, overheating, and potential system failures, ensuring that hydrogen fuel cells operate at their highest efficiency levels. With the global push towards sustainable energy solutions, the advancements in heat exchanger technology are paving the way for more efficient, compact, and high-performance cooling systems. Innovations such as nanomaterials, hybrid cooling solutions, AI-based thermal management, and advanced coolants are set to further enhance hydrogen fuel cell efficiency and reliability. As hydrogen-powered transportation, industrial applications, and renewable energy integration continue to expand, the role of heat exchangers in optimizing fuel cell performance and sustainability will become even more significant. With continued research and technological progress, heat exchanger innovations will contribute to making hydrogen fuel cells a mainstream clean energy solution, supporting a future of zero-emission power generation and carbon neutrality.