How many types of cooling towers ?

Cooling towers are basic components of numerous industrial processes and HVAC systems, and they come in different sorts based on their plan, development, and airflow instrument. The most types of cooling towers include:

Natural Draft Cooling Towers:

- These towers depend on the natural convection of air to make airflow through the tower. They are ordinarily large, hyperbolic-shaped structures with tall chimneys that utilize the stack impact to draw air upwards through the tower. Common draft cooling towers are commonly utilized in high-capacity applications such as power plants and industrial facilities.

Mechanical Draft Cooling Towers:

- Mechanical draft cooling towers utilize fans or blowers to constrain air through the tower, improving airflow and heat exchange effectiveness. They can be encourage classified into two subtypes:

Induced Draft Cooling Towers:

- Fans are found at the beat of the tower, pulling air upwards through the tower. This configuration makes negative weight inside the tower, improving heat exchange productivity and decreasing the hazard of distribution.

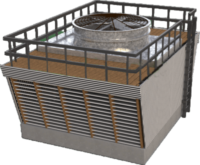

Forced Draft Cooling Towers:

- Fans are found at the base or sides of the tower, pushing air into the tower. This setup strengths air through the tower, expanding wind current speed and heat transfer rates.

Crossflow Cooling Towers:

- Crossflow cooling towers have a flat airflow design, with air streaming on a level plane over the fill fabric whereas water streams vertically downwards. The air enters the tower through louvers on the side and exits through the beat. Crossflow towers are commonly utilized in HVAC systems and medium-sized industrial applications.

Counterflow Cooling Towers:

- Counterflow cooling towers have a vertical airflow design, with air streaming vertically upwards whereas water streams vertically downwards. The air enters the tower through the foot and exits through the best, whereas water is distributed over the fill fabric at the best of the tower. Counterflow towers are known for their productive heat transfer and compact impression, making them reasonable for different industrial applications.

Open Circuit and Closed Circuit Cooling Towers:

Cooling towers can moreover be classified based on whether they operate in an open or closed circuit configuration:

Open Circuit Cooling Towers:

- Water is uncovered to the climate and vanished to scatter heat. A parcel of the water is misplaced through vanishing and drift, requiring cosmetics water to replenish the system.

Closed Circuit Cooling Towers:

- Closed circuit towers circulate a closed-loop coolant (such as glycol or water with added substances) through the tower, which is cooled by implication by the surrounding air. The cooling prepare happens inside a closed loop, minimizing water misfortune and the chance of contamination.

Each type of cooling tower has its advantages and is chosen based on variables such as cooling capacity, effectiveness, space limitations, and environmental considerations.