Hot Water Steam Coils

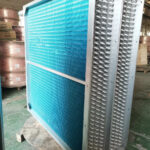

Hot Water Steam Coils are heat exchangers used in HVAC systems to transfer heat from hot water or steam to air. They consist of tubes, usually made of copper or steel, through which hot water or steam flows. These tubes are surrounded by fins, typically made of aluminum, to increase the surface area for heat transfer. As air passes over the heated fins, it warms up, providing space heating in various applications such as commercial buildings, industrial processes, and residential heating systems. Hot water steam coils are efficient, reliable, and essential components in maintaining comfortable indoor temperatures.

Hot Water Steam Coils

Performance of

- Heat Transfer Efficiency: Hot water steam coils are designed to efficiently transfer heat from the hot water or steam flowing through the tubes to the surrounding air. Efficient heat transfer is crucial for maintaining desired indoor temperatures effectively.

- Temperature Control: They provide precise temperature control by regulating the flow of hot water or steam through the coils, ensuring consistent heating of the air passing over the fins.

- Capacity and Heating Output: The capacity of hot water steam coils is measured in terms of their ability to deliver sufficient heat output (in BTU/h or kW) to meet the heating requirements of the space or process they serve.

- Durability and Longevity: Performance also includes the durability of materials used (such as copper or stainless steel tubes) and the overall construction quality, which affects the coil’s lifespan and reliability over time.

- Energy Efficiency: Efficient heat transfer and temperature control contribute to energy savings, making hot water steam coils a cost-effective heating solution in HVAC systems.

- Versatility in Applications: They are versatile in various applications, including commercial buildings, industrial processes, and residential heating, due to their ability to handle different heating demands and environmental conditions.

Hot Water Steam Coils

Energy Efficiency

- Coil Design: Optimal coil design, including fin density and tube arrangement, maximizes surface area for heat transfer, enhancing efficiency.

- Material Selection: Use of high-conductivity materials like copper or stainless steel for tubes and aluminum for fins improves heat transfer efficiency.

- Insulation: Proper insulation around the coils minimizes heat loss and improves thermal efficiency.

- Control Systems: Integration with advanced control systems allows for precise temperature control and efficient operation based on heating demand.

- Variable Speed Drives: Integration of variable speed drives (VSDs) for pumps or fans reduces energy consumption by matching system output to actual demand.

- Maintenance: Regular maintenance, including cleaning coils and replacing filters, ensures optimal performance and prevents energy inefficiencies due to system clogs or malfunctions.

- Efficient Boilers or Steam Generators: Use of high-efficiency boilers or steam generators to produce hot water or steam reduces energy consumption at the source.

Hot Water Steam Coils

Types of

- Standard Hot Water Coils: Designed for heating applications using hot water circulated through the coil tubes.

- Steam Coils: Specifically designed to utilize steam as the heating medium, transferring heat efficiently to the air passing over the coils.

- Booster Coils: Used to supplement heating capacity in HVAC systems, often installed in ductwork to increase air temperature before distribution.

Hot Water Steam Coils

Material and Components of

| Component | Material | Description |

|---|---|---|

| Tubes | Copper, Stainless Steel, | Conducts hot water or steam through the coil, facilitating heat transfer to the surrounding air. |

| Carbon Steel | ||

| Fins | Aluminum, Copper | Increases surface area for heat transfer, enhancing efficiency in heating air passing through. |

| Headers | Brass, Copper, Stainless | Distributes hot water or steam evenly to the tubes, ensuring uniform heating across the coil. |

| Steel | ||

| Manifolds | Steel, Stainless Steel | Collects and directs the flow of hot water or steam to and from the headers and tubes in the coil. |

| Frame | Galvanized Steel, Stainless | Provides structural support and rigidity to the coil assembly, ensuring durability and longevity. |

| Steel | ||

| Coil Casing | Galvanized Steel, | Encloses and protects the tubes, fins, and internal components of the coil from external elements. |

| Stainless Steel, | ||

| Aluminum | ||

| Insulation | Fiberglass, Foam | Reduces heat loss and improves thermal efficiency by minimizing heat transfer to the surroundings. |

| Mounting Brackets | Steel, Aluminum | Securely mounts the coil within HVAC systems or equipment, ensuring stability and proper alignment. |

Other Finned Tube Heat Exchanger We Manufacture

Chilled Water Finned Tube Coils

Chilled Water Finned Tube Coils are components used in HVAC systems for cooling. They consist of a series of tubes with external fins that increase surface area for heat transfer.

Air Handling Unit

Air Handling Unit (AHU) coil is a vital component in HVAC systems, designed to heat or cool air. It comprises tubes through which refrigerant or water circulates and fins that increase

Fin Tube Evaporator Coil

Fin Tube Evaporator coil is a heat exchanger used in air conditioning and refrigeration systems. It consists of copper or aluminum tubes with aluminum fins attached to them.

Fan Coil Unit

Fan Coil Unit (FCU) is a device used in HVAC systems to control the temperature and airflow in a space. It typically consists of a heat exchanger (coil) connected to a fan

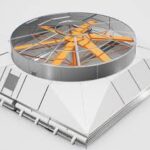

Air Cooled Heat Exchanger

Air Cooled Heat Exchangers (ACHEs) are devices that transfer heat from a fluid (liquid or gas) to the surrounding air. They use finned tubes to increase the surface area for heat transfer

Rice Mill Heat Exchanger

Rice Mill Heat Exchanger is a device used to regulate and control the temperature during various stages of rice milling, such as drying, parboiling, and cooling.

Foundry Sand Cooler

Foundry Sand Cooler is a piece of equipment used in foundries to cool hot sand after it has been used in the casting process. The cooling process is essential to prepare the sand

Air Blast Oil Cooler

Air Blast Oil Cooler is a heat exchanger used to cool hydraulic oil, lubricating oil, or other fluids in industrial machinery and automotive applications.

Aluminum Finned Water Tube Coils

Aluminum Finned Water Tube Coils are heat exchangers used in HVAC systems to transfer heat between air and water. They consist of tubes, typically made of copper or another material