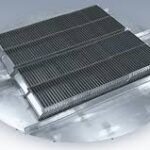

Heat Transfer Coils

Heat Transfer Coils are components used in HVAC systems to either add or remove heat from the air flowing through them. They consist of tubes that carry a heating or cooling medium (like water, steam, or refrigerant) and fins that increase the surface area for efficient heat exchange. As air passes over the coil, it transfers heat to or from the medium inside the tubes, thereby heating or cooling the air. Heat transfer coils are essential for maintaining desired indoor temperatures and are used in various applications, including air handling units, condensers, and evaporators.

Heat Transfer Coils

Versatile Application of

- Commercial Buildings:

- Essential for maintaining comfortable indoor temperatures in offices, shopping malls, hotels, and restaurants.

- Healthcare Facilities:

- Critical for creating sterile environments and regulating temperature and humidity levels in hospitals and clinics.

- Educational Institutions:

- Utilized in schools, universities, and libraries to maintain a conducive learning environment through temperature control.

- Entertainment Venues:

- Necessary for regulating indoor climate in theaters, stadiums, and concert halls for audience comfort during events.

- Food and Beverage Industry:

- Used in processing plants and storage facilities to maintain optimal temperatures for food preservation and safety.

- Pharmaceutical Industry:

- Employed in laboratories and manufacturing facilities to create controlled environments for drug production and research.

- Transportation:

- Integrated into HVAC systems in vehicles, trains, ships, and airplanes to ensure passenger comfort during travel.

Heat Transfer Coils

Material and Components

| Component | Function | Common Materials | Advantages |

|---|---|---|---|

| Tubes | Carry heating or cooling medium | Copper, Stainless Steel | High thermal conductivity, corrosion resistance |

| Fins | Increase surface area for heat exchange | Aluminum, Copper, Galvanized Steel | Lightweight, cost-effective, enhances efficiency |

| Headers and Manifolds | Distribute medium through tubes | Copper, Steel | Even flow distribution, structural support |

| Coatings | Provide protection against corrosion | Epoxy, Phenolic | Enhanced durability, protection in harsh environments |

| Casing | Enclose and support the coil | Galvanized Steel, Aluminum | Structural integrity, protects internal components |

| Connection Points | Interface with HVAC system | Copper, Steel | Secure and reliable connections |

| Drain Pans | Collect and drain condensate | Stainless Steel, Plastic | Prevents water damage, durable |

Heat Transfer Coils

Types of

Heating Coils: These coils use hot water, steam, or electric resistance to raise the temperature of air passing through them.

Cooling Coils: Cooling coils utilize chilled water or refrigerant to lower the temperature of air passing through them.

Steam Coils: Steam coils heat air by passing steam through the coil tubes.

Evaporator Coils: Evaporator coils absorb heat from indoor air to facilitate cooling and dehumidification.

Finned Tube Coils: Finned tube coils have fins attached to the coil tubes, increasing the surface area available for heat transfer.

Plate Coils: Plate coils consist of thin, flat plates with fluid passages for efficient heat transfer.

Other Air Handling Units We Manufacture

Direct Expansion Coils

Direct Expansion Coils also known as evaporator coils, are heat exchangers used in HVAC systems where refrigerant directly absorbs heat from the air passing over the coils

Air Washer Unit

Air Washer Unit is a type of HVAC equipment that combines air cleaning and humidification functions in one system. It uses a water-saturated filter or media

Plenum Box

Plenum Box serves as a junction point in HVAC ductwork, collecting conditioned air from a main supply duct and evenly distributing it to multiple outlets or diffusers throughout a building.

Mist Eliminators

Mist Eliminators, also known as demisters or mist extractors, are devices used to remove liquid droplets (mist) from gas streams. They work by using various mechanisms

Volume Control Dampers

Volume Control Dampers are mechanical devices used in HVAC systems to regulate and control the volume of airflow within ductwork. They adjust the size of the duct opening, typically through adjustable blades