Introduction

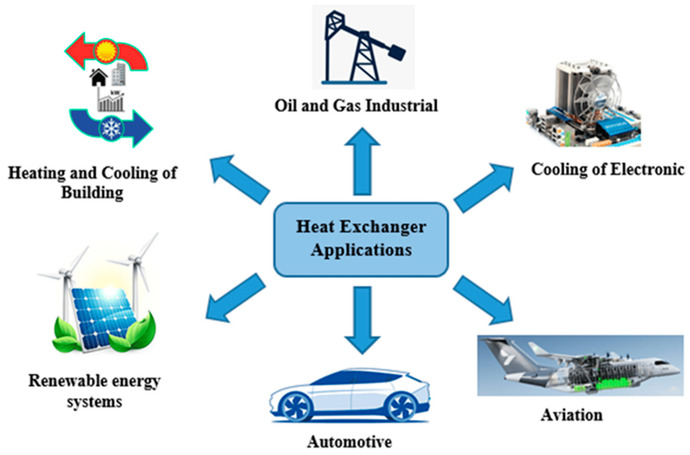

Heat Exchangers Applications are integral components in a wide range of industries, providing an efficient solution for transferring heat between two or more fluids. From cooling and heating applications to waste heat recovery and energy conservation, these devices are crucial in optimizing industrial processes. Their versatility allows them to be used in industries such as pharmaceuticals, oil and gas, food processing, HVAC, and even renewable energy systems. By facilitating precise temperature regulation, heat exchangers contribute to increased system efficiency, reduced energy consumption, and enhanced operational safety. In this article, we will explore the various applications of heat exchangers and their importance in different sectors.

Industrial Heating and Cooling Systems

Heat exchangers are widely used in industrial heating and cooling systems, particularly in large-scale operations like power plants, chemical plants, and oil refineries. These systems manage high-temperature processes such as cooling turbine exhaust gases, engine cooling, and heat recovery from exhausts. The heat exchangers maintain ideal operating conditions for machinery, preventing overheating and enhancing operational safety.

Refrigeration Systems

Heat exchangers are a critical component in refrigeration systems, both in industrial refrigeration and residential air conditioning. In these systems, heat exchangers absorb heat from a cold substance (like refrigerant gas) and release it into a warm environment (such as outside air). This process is essential for temperature regulation in industries like food storage, pharmaceuticals, and beverage manufacturing, where precise temperature control is crucial for preserving quality.

HVAC Systems

In HVAC (Heating, Ventilation, and Air Conditioning) systems, heat exchangers help regulate indoor climate by transferring heat between air and fluids. In heating applications, heat exchangers pull heat from warm air or fluids and circulate it into the building’s living or working spaces. In cooling applications, they remove heat from indoor air and expel it outside. Modern HVAC systems are designed to optimize energy use, and heat exchangers improve efficiency by recovering heat, reducing the need for additional heating or cooling energy.

Marine Applications

In the maritime industry, heat exchangers are indispensable for ensuring the efficient operation of vessels. They are used to cool engine coolants, lubricating oils, and the water used in various onboard systems. Marine heat exchangers help prevent overheating of engines by transferring excess heat to sea water or air. They are also used for ballast water treatment systems, where they manage the temperature of ballast water before it is discharged into the ocean, ensuring compliance with environmental regulations.

Pharmaceutical and Biotech Industries

In the pharmaceutical and biotech industries, precise temperature control is essential to maintain the integrity of sensitive products like vaccines, biologics, and medicines. Heat exchangers are used in various stages of production, such as fermentation, distillation, and drying processes. In fermentation, for example, heat exchangers regulate the temperature of the fermenter to optimize microbial growth conditions. They also provide thermal regulation in cleanrooms, where maintaining specific temperatures is crucial for the production of pharmaceutical products.

Renewable Energy Systems

Heat exchangers play a key role in renewable energy applications like solar thermal systems and geothermal energy plants. In solar thermal energy, heat exchangers transfer collected solar heat to water or another fluid for storage or direct use. This stored thermal energy can be used for space heating, hot water supply, or electricity generation. In geothermal systems, heat exchangers transfer heat from underground sources to surface-level systems, where it can be used for power generation or heating.

Oil and Gas Industry

In the oil and gas industry, heat exchangers are used in multiple applications, such as crude oil refining, natural gas processing, and the transportation of heat-sensitive fluids. They are employed to cool or heat hydrocarbons during the distillation and liquefaction processes in refineries. In offshore platforms, heat exchangers ensure that equipment like turbines and engines operate at safe temperatures.

Food Processing and Dairy

Heat exchangers in the food processing industry are used for pasteurization, sterilization, and cooling. For example, in dairy plants, they help maintain milk at specific temperatures for pasteurization, which kills harmful bacteria without compromising the product’s flavor or nutritional value. Heat exchangers are also used to rapidly cool food products like juices, soups, and sauces after they have been heated, preserving their quality and extending shelf life.

Electric Vehicle (EV) Battery Cooling

As the electric vehicle market grows, heat exchangers have become vital in managing the thermal performance of lithium-ion batteries used in electric cars. These batteries generate heat during charge and discharge cycles, and excessive heat can degrade battery performance and lifespan. Heat exchangers in EVs help maintain optimal battery temperatures, improving efficiency and ensuring that the battery operates safely.

Heat Recovery Systems

Heat recovery systems in industrial processes use heat exchangers to capture waste heat from exhaust gases or hot fluids and repurpose it to preheat incoming fluids, reduce energy consumption, and lower operational costs. These systems are used in industries such as cement production, steel manufacturing, and chemical processing, where high-temperature exhaust gases are produced. Instead of letting this energy go to waste, heat exchangers capture the heat and use it to improve the efficiency of the process.

Automotive Industry

Heat exchangers in the automotive industry serve crucial functions, especially in maintaining engine and cabin temperatures. In engine cooling systems, heat exchangers, specifically radiators, absorb excess heat from the engine coolant and transfer it to the surrounding air. They ensure that the engine runs at optimal temperatures, preventing overheating and improving fuel efficiency.

Wastewater Treatment

Heat exchangers are also employed in wastewater treatment plants to regulate the temperature of water in various stages of treatment. For example, they are used to control the temperature of incoming or outgoing water to prevent microbial growth or freezing in colder climates. Heat exchangers help maintain optimal conditions for biological treatment processes, such as aerobic digestion, which relies on specific temperatures to break down organic matter efficiently.

Conclusion

Heat Exchangers Applications are indispensable in modern industry, serving a critical role in maintaining optimal temperatures and improving energy efficiency across diverse applications. Whether it’s for cooling turbine engines, regulating temperatures in refrigeration systems, or capturing waste heat for reuse, heat exchangers are essential for reducing operational costs and enhancing system performance. As industries continue to evolve, the demand for innovative heat transfer solutions will only grow. By understanding the various applications of heat exchangers, businesses can make informed decisions to optimize their operations, reduce energy consumption, and contribute to a more sustainable future.