Introduction

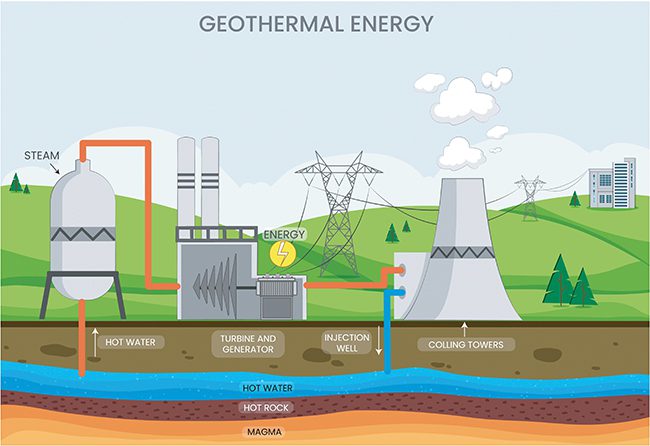

Geothermal power plants utilize the Earth’s internal heat to generate electricity, making them a sustainable and eco-friendly alternative to fossil fuel-based power plants. These plants rely on underground reservoirs of steam or hot water, which are extracted to drive turbines. However, after energy extraction, the residual heat must be efficiently removed to maintain plant performance and prevent equipment damage. Cooling towers play a critical role in geothermal power plants by dissipating excess heat into the atmosphere, allowing the power cycle to continue. Unlike traditional power plants, geothermal plants face unique challenges, such as handling mineral-rich water, managing high corrosion risks, addressing environmental concerns, and optimizing water usage. Understanding these factors is essential for designing efficient and long-lasting cooling systems in geothermal power applications.

Key Considerations for Cooling Towers in Geothermal Power Plants

High Mineral Content and Scaling Issues

- Geothermal water contains a high concentration of dissolved minerals, including silica, calcium carbonate, and sulfates.

- When the hot geothermal water cools inside the tower, these minerals tend to precipitate and form scale deposits on the heat exchanger tubes, pipes, and tower surfaces.

- Scaling reduces heat transfer efficiency, clogs pipelines, and leads to frequent maintenance and operational downtime.

- Solutions include:

- Chemical treatments such as anti-scalants and pH control to prevent scale formation.

- Physical filtration methods, such as sand filters and membrane systems, to remove suspended solids.

- Blowdown management, where a portion of the water is periodically removed and replaced to control mineral concentrations.

Corrosion Challenges

- Geothermal fluids often contain highly corrosive elements, such as:

- Hydrogen sulfide (H₂S), which forms acidic compounds.

- Chlorides, which accelerate metal corrosion.

- Other acidic components that weaken structural materials over time.

- If not managed properly, corrosion can reduce the lifespan of cooling tower components and increase maintenance costs.

- Strategies to mitigate corrosion include:

- Material selection: Using stainless steel (SS 316, SS 316L), fiberglass-reinforced plastic (FRP), titanium coatings, and epoxy-lined carbon steel to resist corrosion.

- Protective coatings: Applying anti-corrosion coatings such as ceramic-based paints, polymer linings, and nanocoatings.

- Routine inspections and monitoring to detect early signs of corrosion and take preventive actions.

Water Consumption and Conservation

- Geothermal power plants rely on large quantities of water for cooling, making water conservation a key challenge.

- Many geothermal plants are located in arid or water-scarce regions, where water availability is limited.

- Solutions to optimize water usage include:

- Drift eliminators: These reduce water loss by capturing and redirecting small droplets back into the cooling system.

- Hybrid cooling systems: A combination of wet and dry cooling methods to optimize efficiency while minimizing water consumption.

- Closed-loop cooling: Unlike traditional open cooling systems, closed-loop designs recycle and reuse water, significantly reducing wastage.

Environmental Impact and Regulations

- Cooling towers in geothermal plants can impact local ecosystems by discharging warm water, minerals, and chemical residues into nearby water bodies.

- Stricter environmental regulations require power plants to:

- Monitor water quality and control chemical discharge levels.

- Reduce thermal pollution by implementing advanced heat exchange technologies.

- Adopt zero-liquid discharge (ZLD) systems, which completely recycle water, ensuring no waste is released into the environment.

- Regulatory bodies such as EPA (Environmental Protection Agency) and local water authorities set guidelines for cooling tower operation, making compliance crucial for sustainable operations.

Efficient Heat Dissipation

- Geothermal plants operate continuously, meaning cooling towers must function efficiently under variable loads.

- Advanced heat dissipation techniques include:

- Multi-cell cooling towers, which allow flexibility by operating only the required number of cells based on heat load.

- Improved airflow management using advanced fan designs, such as variable-speed fans that adjust to changing cooling demands.

- Enhanced heat exchanger surfaces that improve thermal conductivity and cooling performance.

Use of Alternative Fluids

- Some geothermal plants use binary cycle systems, where geothermal heat is transferred to a secondary working fluid (such as organic fluids like isobutane or ammonia).

- These alternative fluids have different thermal and chemical properties, requiring cooling towers to be:

- Custom-designed for specific fluid properties.

- Made of special materials to prevent degradation due to chemical interactions.

Drift and Emission Control

- Cooling towers release tiny water droplets (drift) into the atmosphere, carrying dissolved minerals and chemicals that can contaminate surrounding land and water sources.

- To reduce drift emissions:

- High-efficiency drift eliminators are installed to capture water droplets before they escape.

- Chemical treatments prevent the release of harmful substances.

- Proper tower placement ensures emissions are directed away from sensitive areas.

Future Innovations in Geothermal Cooling Tower Technology

- Advanced Nanocoatings for Corrosion Protection

- Nano-based coatings provide ultra-thin protective layers, improving corrosion resistance and extending cooling tower lifespan.

- Hybrid Cooling Systems

- Combining wet and dry cooling minimizes water usage while ensuring optimal cooling efficiency.

- AI and IoT-Based Monitoring

- Artificial Intelligence (AI) and Internet of Things (IoT) enable real-time monitoring of cooling tower performance.

- Sensors detect temperature, humidity, scaling, and corrosion, allowing predictive maintenance and reducing unexpected failures.

- Enhanced Water Treatment Solutions

- Electromagnetic water treatment prevents scaling without chemicals.

- Membrane filtration technologies improve water recycling and purification.

- Direct Contact Condensers

- Some geothermal plants are eliminating cooling towers by using direct contact condensers that release steam directly into the air, reducing system complexity.

Conclusion

Geothermal Power Plants are an essential component of geothermal power plants, ensuring efficient heat dissipation and operational stability. However, geothermal applications present unique challenges, including scaling, corrosion, and water conservation. By adopting advanced materials, optimizing cooling strategies, and integrating new technologies, geothermal power plants can enhance cooling tower efficiency while minimizing environmental impact. With ongoing innovations such as hybrid cooling systems, AI-powered monitoring, and advanced coatings, the future of geothermal cooling towers looks promising. As global energy demand grows and sustainability becomes a priority, optimizing cooling tower performance will play a crucial role in maximizing the potential of geothermal power generation.