FRP Casing

FRP Casing refers to casings or enclosures made from Fiberglass Reinforced Plastic (FRP). FRP is a composite material consisting of a polymer matrix reinforced with fiberglass fibers. FRP casings are valued for their lightweight yet strong construction, resistance to corrosion from chemicals and weather, and durability in harsh environments. They are commonly used in industries such as chemical processing, water treatment, and marine applications where traditional materials like metal may corrode or degrade quickly.

FRP Casing

Functional Advantages of

- Corrosion Resistance: FRP casings are highly resistant to corrosion from chemicals, moisture, and weathering, making them suitable for harsh environments where metal casings might deteriorate.

- Structural Integrity: They provide structural support and protection for equipment and components, ensuring durability and longevity.

- Lightweight: Compared to metal alternatives, FRP casings are lightweight, which facilitates easier handling, installation, and maintenance.

- Electrical Insulation: FRP is non-conductive, offering electrical insulation in applications where this property is essential for safety.

- Design Flexibility: They can be molded into various shapes and sizes, allowing for custom designs that meet specific functional and aesthetic requirements.

- Temperature Resistance: Casings can withstand a wide range of temperatures, making them suitable for both hot and cold environments.

- Environmental Resistance: They resist UV radiation, making them suitable for outdoor installations without significant degradation.

FRP Casing

Types of

- Molded FRP Casings for Cooling Towers: Formed through molding processes, providing custom shapes and sizes for cooling tower applications.

- Pultruded FRP Casings for Cooling Towers: Made via pultrusion, offering high strength and corrosion resistance tailored for cooling tower environments.

FRP Casing

Role and Benefits of

- Protection: Provides structural integrity and protection for internal components or equipment.

- Corrosion Resistance: Guards against corrosion from chemicals, moisture, and weather.

- Insulation: Offers electrical insulation where needed.

- Durability: Ensures long-term reliability and performance in harsh environments.

Other Cooling Tower Spares We Manufacture

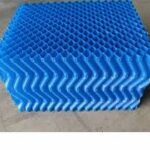

Honeycomb PVC Fills

Honeycomb PVC Fills are a type of fill media used in cooling towers, made from polyvinyl chloride (PVC). They feature a honeycomb-like structure that maximizes the surface area

Drift Eliminators

Drift Eliminators are essential components in cooling towers designed to minimize the loss of water droplets, known as drift, that are carried out of the tower by the exiting airflow.

Axial Fan

Axial Fan is a type of fan that moves air along the axis of its blades. It typically consists of a motor and blades mounted on a shaft within a cylindrical housing. Axial fans are designed

Motors

Motors are specially designed electric motors used to drive fans in cooling towers. They are typically robust and corrosion-resistant, often made of materials like stainless steel

Distribution Pipes

Distribution Pipes are essential components of infrastructure systems used to convey fluids from a central source to multiple endpoints for consumption or use.

Sprinkler

Sprinkler in cooling towers are mechanical devices designed to evenly distribute water over the fill media inside the tower. They play a crucial role in the cooling process

Nozzles

Nozzles in cooling towers are devices designed to distribute water evenly over the fill material inside the tower. They play a critical role in facilitating efficient heat transfer

Gearbox

Gearbox in a cooling tower is a mechanical component that serves to transmit and control the rotational speed and torque of the fan or other moving parts within the tower.

Structure and Hardware

Structure and Hardware of a cooling tower encompass its physical framework and essential components designed to facilitate heat dissipation.