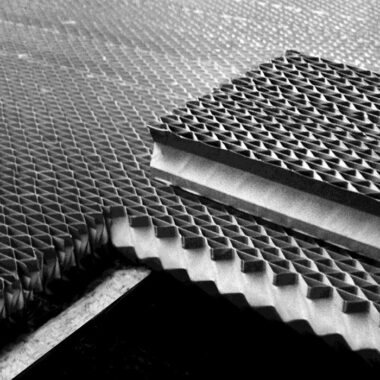

Drift Eliminators

Drift Eliminators are essential components in cooling towers designed to minimize the loss of water droplets, known as drift, that are carried out of the tower by the exiting airflow. These eliminators work by creating a complex path for the air to follow, causing water droplets to collide with the surfaces of the eliminator and coalesce into larger droplets. These larger droplets then fall back into the cooling tower rather than being expelled into the environment.

Drift Eliminators

Characteristics of

- High Efficiency: Designed to capture and redirect a large percentage of water droplets, minimizing water loss.

- Low Airflow Resistance: Engineered to allow air to pass through with minimal resistance, maintaining the efficiency of the cooling tower’s ventilation system.

- Durability: Made from materials resistant to corrosion, UV radiation, and biological growth, ensuring long-lasting performance.

- Compact Design: Typically constructed in modular sections that are easy to install and maintain within the cooling tower.

- Chemical Resistance: Able to withstand exposure to the chemicals used in cooling tower water treatment without degrading.

- Maintenance-Friendly: Designed for easy cleaning and maintenance to ensure ongoing effective performance.

- Environmental Compliance: Helps cooling towers meet environmental regulations by reducing the emission of drift droplets.

Drift Eliminators

Functions and Importance of

- Minimizing Water Loss: Capturing water droplets from the exhaust air and redirecting them back into the cooling tower, thereby conserving water resources.

- Environmental Protection: Preventing the release of potentially contaminated water droplets into the surrounding environment, ensuring compliance with environmental regulations.

- Maintaining Equipment Integrity: Protecting nearby equipment and structures from water damage caused by drifting droplets, thereby extending their operational lifespan.

- Enhancing Efficiency: Facilitating the efficient operation of the cooling tower by reducing the load on downstream equipment and optimizing heat exchange processes.

- Cost Savings: Contributing to cost reduction through lower water consumption, decreased maintenance needs, and improved overall system efficiency.

Other Cooling Tower Spares We Manufacture

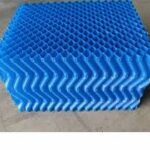

Honeycomb PVC Fills

Honeycomb PVC Fills are a type of fill media used in cooling towers, made from polyvinyl chloride (PVC). They feature a honeycomb-like structure that maximizes the surface area

Axial Fan

Axial Fan is a type of fan that moves air along the axis of its blades. It typically consists of a motor and blades mounted on a shaft within a cylindrical housing. Axial fans are designed

Motors

Motors are specially designed electric motors used to drive fans in cooling towers. They are typically robust and corrosion-resistant, often made of materials like stainless steel

FRP Casing

FRP Casing refers to casings or enclosures made from Fiberglass Reinforced Plastic (FRP). FRP is a composite material consisting of a polymer matrix reinforced with fiberglass fibers.

Distribution Pipes

Distribution Pipes are essential components of infrastructure systems used to convey fluids from a central source to multiple endpoints for consumption or use.

Sprinkler

Sprinkler in cooling towers are mechanical devices designed to evenly distribute water over the fill media inside the tower. They play a crucial role in the cooling process

Nozzles

Nozzles in cooling towers are devices designed to distribute water evenly over the fill material inside the tower. They play a critical role in facilitating efficient heat transfer

Gearbox

Gearbox in a cooling tower is a mechanical component that serves to transmit and control the rotational speed and torque of the fan or other moving parts within the tower.

Structure and Hardware

Structure and Hardware of a cooling tower encompass its physical framework and essential components designed to facilitate heat dissipation.