Introduction

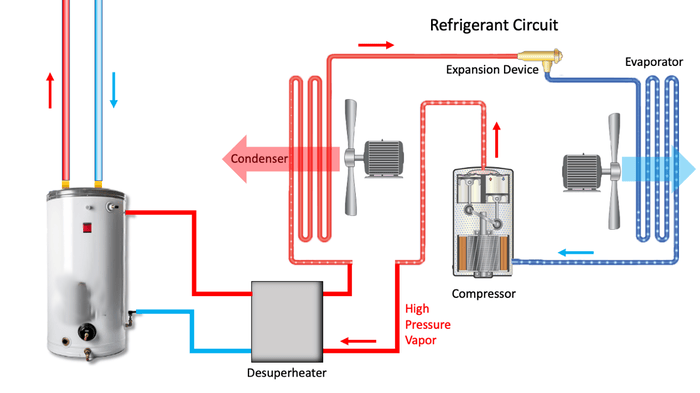

Desuperheaters are integral components in modern chiller systems, playing a pivotal role in improving their overall performance and efficiency. In refrigeration cycles, superheating occurs when the refrigerant gas, after being compressed, is heated beyond its saturation point. While this superheated gas is essential for the cooling process, if left unchecked, it can increase the load on subsequent components such as condensers and compressors. This is where desuperheaters come into play. These devices help regulate the temperature of the superheated refrigerant gas by cooling it down before it enters the condenser. As a result, desuperheaters optimize the refrigeration process, enhance energy efficiency, and protect sensitive system components from damage caused by excessive heat. This process not only improves the operational efficiency of the chiller but also leads to cost savings and prolonged system life. In various industries, including HVAC, industrial refrigeration, and air conditioning, desuperheaters are increasingly being recognized for their ability to ensure stable and reliable cooling performance.

Key Features and Benefits of Desuperheaters for Chillers:

- Efficient Energy Use: Desuperheaters play a key role in energy efficiency by cooling the superheated refrigerant vapor before it reaches the condenser. This reduces the workload on the condenser, which can then operate more effectively and with less energy consumption. In turn, this lowers the operational costs of the chiller system.

- Improved System Performance: By regulating the temperature of the refrigerant entering the condenser, desuperheaters ensure that the system performs at its best. This leads to more effective heat exchange and helps the chiller maintain a consistent temperature, especially in high-demand environments. More efficient operation improves the overall performance and stability of the cooling system.

- Protection of Components: Superheated refrigerant vapor can cause damage to sensitive components within the chiller, including the compressor and condenser. By reducing the temperature of the vapor before it enters these components, desuperheaters help prevent overheating and protect the chiller’s internal parts from excessive wear and tear, ultimately extending the lifespan of the system.

- Enhanced Heat Transfer Efficiency: Desuperheaters enhance the heat transfer process by lowering the temperature of the refrigerant. This process helps to improve the effectiveness of the chiller’s condenser, enabling the refrigerant to condense more efficiently and release the absorbed heat at a faster rate. As a result, the cooling process becomes more efficient, and the chiller operates at a higher capacity.

- Environmental Benefits: By improving the energy efficiency of the chiller system, desuperheaters contribute to reducing the overall carbon footprint of refrigeration systems. Lower energy consumption means fewer emissions and a more environmentally friendly operation, which is increasingly important in today’s eco-conscious world.

Applications of Desuperheaters for Chillers:

- HVAC Systems: In large commercial buildings and industrial facilities, desuperheaters are used in chiller systems to ensure that cooling is efficient and stable, especially during high-load periods. These systems require precise temperature control, which desuperheaters help achieve by regulating refrigerant temperatures before they enter the condenser.

- Industrial Refrigeration: Desuperheaters are vital in industrial refrigeration applications, such as cold storage and food processing plants. These environments require continuous cooling, and desuperheaters ensure that the chiller systems operate at optimal efficiency, even in demanding conditions.

- Air Conditioning Systems: In larger air conditioning systems, such as those found in high-rise buildings or manufacturing facilities, desuperheaters help maintain consistent temperatures. By cooling the superheated refrigerant gas before it enters the condenser, they ensure that the system runs smoothly and efficiently.

- Chemical and Petrochemical Plants: In industries where precise temperature control is essential for safety and process efficiency, desuperheaters help manage the thermal properties of refrigerants used in chillers, ensuring that the cooling systems operate without overloading and provide steady cooling performance.

Future Trends and Innovations:

- Smart and IoT Integration: The integration of smart technology and Internet of Things (IoT) devices into desuperheaters is on the rise. Sensors can monitor the temperature, pressure, and flow of refrigerant in real time, allowing for dynamic adjustments to optimize performance. These innovations enable predictive maintenance, where issues are detected before they become critical, further enhancing the efficiency and lifespan of chiller systems.

- Advanced Materials for Better Performance: As the demand for energy-efficient solutions grows, advancements in materials technology are also expected to play a role in the development of desuperheaters. New materials with better heat transfer properties, as well as those resistant to corrosion and wear, could improve the effectiveness and durability of desuperheaters, allowing them to perform efficiently under harsher conditions and longer periods.

- Hybrid Desuperheaters: Future desuperheaters may incorporate hybrid designs that combine the functions of desuperheating with additional cooling or heat recovery systems. This could result in even higher efficiency levels by integrating multiple processes, such as recovering waste heat for use elsewhere in the system.

- Energy Recovery Integration: Desuperheaters are likely to be integrated with energy recovery systems in the future. These systems could capture the waste heat from the refrigerant and repurpose it for other uses, such as heating water or air. This would create a more sustainable and circular energy system, reducing overall energy consumption and costs.

Conclusion

Desuperheaters are essential in maximizing the efficiency and longevity of chiller systems. By cooling the superheated refrigerant before it enters the condenser, desuperheaters contribute to better heat exchange, lower energy consumption, and the protection of crucial system components. These devices are becoming increasingly important in various applications, including HVAC, industrial refrigeration, and large-scale air conditioning systems, where precise temperature regulation is necessary. The evolution of desuperheaters, driven by advancements in smart technologies, materials, and energy recovery systems, promises even greater improvements in energy efficiency and sustainability. As industries continue to prioritize environmental impact and cost savings, desuperheaters will play a key role in shaping the future of cooling technologies, offering enhanced performance and operational reliability for years to come.