Cooling towers are heat rejection devices that transfer waste heat from industrial processes to the atmosphere through the process of evaporation. The working principle of a cooling tower involves the removal of heat from a process stream by bringing it into contact with air and allowing a portion of the water to evaporate, carrying away the heat. Here’s a brief overview of the Cooling Tower Working Principle and Methods :

Working Principle:

1 Hot Water Inlet:

Hot water from industrial processes is circulated into the cooling tower.

2 Distribution System:

The hot water is distributed over the fill media or packing inside the cooling tower. The fill media provides a large surface area for water to come into contact with air.

3 Airflow:

Air is induced or forced through the fill media by fans located at the top of the cooling tower. The contact between the hot water and the air promotes evaporation.

4 Evaporation:

As the hot water cascades over the fill media, a portion of it evaporates due to the contact with the air. This process absorbs heat from the remaining water, cooling it down.

5 Heat Dissipation:

The heat absorbed during evaporation is dissipated into the atmosphere as the warm, moist air rises through the cooling tower.

6 Cooled Water Outlet:

The cooled water is collected at the bottom of the cooling tower and returned to the industrial process for further use.

Methods:

1 Natural Draft Cooling Towers:

The natural draft cooling towers are commonly used in industrial facilities where the total heat rate is at the level of approximately 450 MW. They are only used for applications where a large constant cooling requirement over many years is required

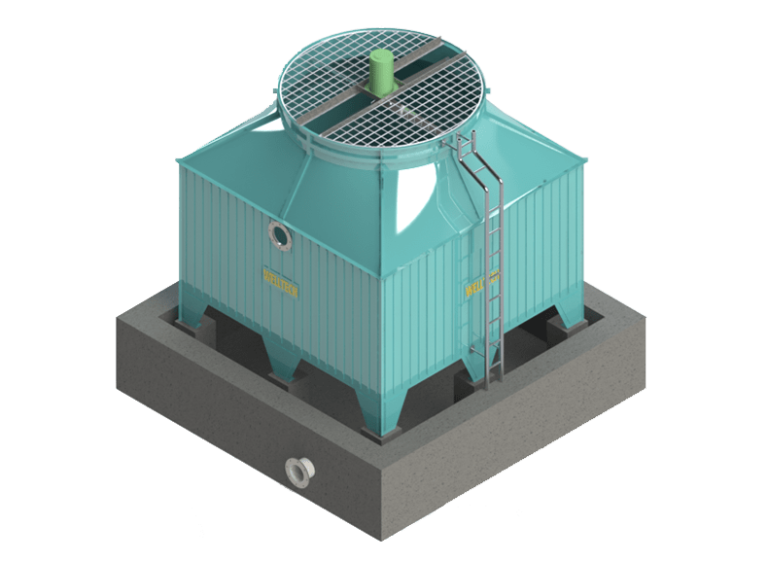

2 Mechanical Draft Cooling Towers:

Mechanical draft towers use fans to force or induce air through the tower, providing better control over the airflow. There are two types:

- Induced Draft: Fans are placed at the top, creating a negative pressure that pulls air through the tower.

- Forced Draft: Fans are located at the bottom, pushing air through the tower.

3 Crossflow and Counterflow Design:

- In crossflow cooling towers, air flows horizontally across the downward flow of water.

- In counterflow cooling towers, air flows vertically upwards against the falling water. Counterflow design is more efficient in terms of heat transfer.

4 Cooling Tower Fill Media:

The fill media inside the cooling tower can be of various types, such as splash fill or film fill, providing a surface for the water to spread out and enhance contact with the air.

5 Water Treatment:

Proper water treatment is essential to prevent scale, corrosion, and biological growth in the cooling tower system, ensuring efficient heat transfer and system longevity.

Understanding these Cooling Tower Working Principle and Methods helps in the proper design, operation, and maintenance of cooling towers for effective heat dissipation in industrial processes.