Brazed Plate Heat Exchanger

Brazed Plate Heat Exchanger (BPHE) is a type of heat exchanger that incorporates several corrugated plates with a brazing material between each plate. The space between two adjacent plates forms the channel through which the fluids flow. The brazing material forms joints at every contact point between the plates during the vacuum-brazing process1.

Brazed Plate Heat Exchanger

Installation for

- The BPHE should be mounted in an upright position.

- Use flexible hoses or vibration dampers to reduce pulsation to protect the heat exchanger against vibration, thermal and hydraulic induced stress.

- All items should be supported independently.

| DRAUGHT TYPE/ SHAPE | FLOW TYPE | MOC | CAPACITY (TR) | FILL TYPE | DRIVE TYPE |

|---|---|---|---|---|---|

| Induced / Square | Counter Flow | FRP | 10 – 500 | Honeycomb Fills | Direct |

Brazed Plate Heat Exchanger

Application for

- Condenser

- Evaporator

- Sub Cooler

- Economizer

- Pre-Cooler

- Inter-Cooler

- Water Cooler

- Oil Cooler

Cleaning

While fouling on the BPHE, it is possible to remove most of the soft debris that is blocking the inside circuit by back flushing. Weak acids with concentration less than 5%; for example: citric, acid oxalic acid add in a tank. Circulate the cleaning solution. Before restarting the system, flush the plate heat exchanger with large amounts of fresh water to purge any remaining acid solution. If the acidity is too high, the copper and stainless steel inside the BPHE may be etched or corroded.

Other Plate Heat Exchanger We Manufacture

Gasketed Plate Heat Exchanger

Gasketed Plate Heat Exchangers use thin, corrugated plates in a frame, sealed with gaskets, to efficiently transfer heat between fluids.

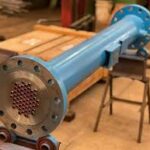

Shell and Tube Condenser

Shell and Tube Condenser is a type of heat exchanger used to condense steam or vapor into liquid. It consists of a series of tubes enclosed within a cylindrical shell.

Shell and Tube Evaporator

Evaporator is a device used in refrigeration and air conditioning systems to absorb heat from its surroundings and evaporate a refrigerant. It operates by allowing the refrigerant

Shell and Tube After Coolers

Shell and Tube After Coolers are heat exchangers designed to cool compressed air or gases after they have been compressed by a compressor they consist of a bundle of tubes

Shell and Tube Inter Coolers

Shell and Tube Inter Coolers is a type of heat exchanger commonly used in various industrial applications to cool fluids or gases. It consists of a series of tubes (tube bundle)

Shell and Tube Oil Coolers

Shell and Tube Oil Coolers are a type of heat exchanger commonly used in industrial applications to cool oil. These coolers consist of a series of tubes (tube bundle)