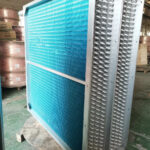

Aluminum Finned Water Tube Coils

Aluminum Finned Water Tube Coils are heat exchangers used in HVAC systems to transfer heat between air and water. They consist of tubes, typically made of copper or another material, through which water flows. These tubes are surrounded by aluminum fins, which increase the surface area for heat exchange. The fins enhance the efficiency of heat transfer by facilitating better contact between the air and the water-carrying tubes. These coils are commonly used in air handling units, fan coil units, and other heating and cooling applications to improve thermal performance and energy efficiency.

Aluminum Finned Water Tube Coils

Key Specification on

- Tube Material: Typically copper, but can also be stainless steel or other materials depending on the application.

- Fin Material: Aluminum Finned Water Tube, chosen for its excellent thermal conductivity and lightweight properties.

- Tube Diameter: Common diameters range from 3/8 inch to 5/8 inch, depending on the specific design and application requirements.

- Fin Density: Measured in fins per inch (FPI), typically ranging from 8 to 16 FPI, which affects the heat transfer efficiency and airflow resistance.

- Tube Configuration: Various configurations such as staggered or in-line tube arrangements to optimize heat transfer.

- Coil Dimensions: Length, width, and height of the coil, customized to fit the specific HVAC system requirements.

- Fin Thickness: Typically ranges from 0.004 to 0.016 inches, influencing the durability and heat transfer rate.

- Heat Transfer Capacity: Measured in BTU/h (British Thermal Units per hour) or kW (kilowatts), indicating the amount of heat the coil can transfer.

- Working Pressure: Maximum pressure the coil can withstand, commonly up to 300 psi, depending on the material and construction.

- Temperature Range: Operational temperature range the coil can handle, typically from -20°F to 250°F (-29°C to 121°C).

Aluminum Finned Water Tube Coils

Advantages of

- High thermal conductivity: Efficient heat transfer between water and air.

- Lightweight: Easier to handle and install.

- Corrosion resistance: Longevity and durability in various environments.

- Improved heat transfer efficiency: Greater surface area for better heat exchange.

- Cost-effective: Lower material and manufacturing costs.

- Easy to manufacture: Simplified production processes.

- Enhanced durability: Withstands wear and tear over time.

- Flexibility in design: Customizable for different applications and sizes.

- Low maintenance requirements: Reduced need for frequent servicing.

- High performance in diverse applications: Suitable for HVAC, refrigeration, and industrial systems.

Aluminum Finned Water Tube Coils

Application of

- HVAC Systems: Used in air handling units (AHUs), fan coil units (FCUs), and rooftop units for heating and cooling air in residential, commercial, and industrial buildings.

- Refrigeration: Employed in refrigeration systems for supermarkets, cold storage, and food processing facilities to maintain optimal temperatures.

- Heat Pumps: Integral components in heat pump systems, enhancing the efficiency of heat transfer for both heating and cooling modes.

- Data Centers: Utilized in cooling systems to regulate temperature and humidity, ensuring the optimal performance and longevity of sensitive equipment.

- Automotive: Used in vehicle heating and air conditioning systems to provide climate control within the passenger cabin.

Other Finned Tube Heat Exchanger We Manufacture

Chilled Water Finned Tube Coils

Chilled Water Finned Tube Coils are components used in HVAC systems for cooling. They consist of a series of tubes with external fins that increase surface area for heat transfer.

Air Handling Unit

Air Handling Unit (AHU) coil is a vital component in HVAC systems, designed to heat or cool air. It comprises tubes through which refrigerant or water circulates and fins that increase

Fin Tube Evaporator Coil

Fin Tube Evaporator coil is a heat exchanger used in air conditioning and refrigeration systems. It consists of copper or aluminum tubes with aluminum fins attached to them.

Fan Coil Unit

Fan Coil Unit (FCU) is a device used in HVAC systems to control the temperature and airflow in a space. It typically consists of a heat exchanger (coil) connected to a fan

Hot Water Steam Coils

Hot Water Steam Coils are heat exchangers used in HVAC systems to transfer heat from hot water or steam to air. They consist of tubes, usually made of copper or steel,

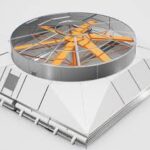

Air Cooled Heat Exchanger

Air Cooled Heat Exchangers (ACHEs) are devices that transfer heat from a fluid (liquid or gas) to the surrounding air. They use finned tubes to increase the surface area for heat transfer

Rice Mill Heat Exchanger

Rice Mill Heat Exchanger is a device used to regulate and control the temperature during various stages of rice milling, such as drying, parboiling, and cooling.

Foundry Sand Cooler

Foundry Sand Cooler is a piece of equipment used in foundries to cool hot sand after it has been used in the casting process. The cooling process is essential to prepare the sand

Air Blast Oil Cooler

Air Blast Oil Cooler is a heat exchanger used to cool hydraulic oil, lubricating oil, or other fluids in industrial machinery and automotive applications.