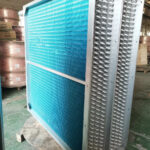

Air Cooled Heat Exchanger

Air Cooled Heat Exchangers (ACHEs) are devices that transfer heat from a fluid (liquid or gas) to the surrounding air. They use finned tubes to increase the surface area for heat transfer, with fans blowing air over these tubes to dissipate the heat. ACHEs are widely used in industries like petrochemical, power generation, and chemical processing, especially in regions where water is scarce or unsuitable for cooling. They offer advantages such as water conservation and lower operational costs but require more space and can generate significant noise. These exchangers are critical in applications where efficient air cooling is necessary.

Air Cooled Heat Exchanger

Types of Fins in

- Plain Fins: Simple, flat fins attached to tubes that provide basic heat transfer capabilities and are easy to manufacture and maintain.

- Serrated Fins: Fins with small cuts or serrations along their edges that increase air flow turbulence and enhance heat transfer efficiency.

- Spiral Fins: Helically wound fins around the tubes that provide a larger surface area for heat exchange and improve heat transfer by creating a spiraling air flow.

- Louvered Fins: Fins with small, angled cuts creating louvers that disrupt laminar flow, increase turbulence, and enhance heat transfer performance.

- Perforated Fins: Fins containing small holes or perforations that increase air flow turbulence and enhance heat transfer efficiency for high-performance applications.

- Wavy Fins: Fins with a wavy pattern along their surface that increase the contact area and turbulence, leading to improved heat transfer efficiency.

Air Cooled Heat Exchanger

Future of

- Energy Efficiency: Continued focus on energy-efficient designs to reduce operational costs and environmental impact. Innovations in fan technology, materials, and control systems aim to improve overall efficiency.

- Environmental Regulations: Stricter environmental regulations worldwide drive the adoption of ACHEs due to their lower water consumption and reduced environmental footprint compared to water-cooled systems.

- Advanced Materials: Use of advanced materials such as alloys and coatings to enhance corrosion resistance, durability, and heat transfer efficiency.

- Smart Technologies: Integration of smart technologies, including IoT-enabled sensors and predictive maintenance systems, for real-time monitoring, optimization, and remote management.

- Modularity and Flexibility: Increasing demand for modular and flexible designs that can be easily integrated into existing infrastructure or scaled up/down based on operational needs.

- Noise Reduction: Continued development of noise reduction technologies to minimize operational noise, making ACHEs suitable for urban and noise-sensitive environments.

Air Cooled Heat Exchanger

Comparison of Configuration in

Other Finned Tube Heat Exchanger We Manufacture

Chilled Water Finned Tube Coils

Chilled Water Finned Tube Coils are components used in HVAC systems for cooling. They consist of a series of tubes with external fins that increase surface area for heat transfer.

Air Handling Unit

Air Handling Unit (AHU) coil is a vital component in HVAC systems, designed to heat or cool air. It comprises tubes through which refrigerant or water circulates and fins that increase

Fin Tube Evaporator Coil

Fin Tube Evaporator coil is a heat exchanger used in air conditioning and refrigeration systems. It consists of copper or aluminum tubes with aluminum fins attached to them.

Fan Coil Unit

Fan Coil Unit (FCU) is a device used in HVAC systems to control the temperature and airflow in a space. It typically consists of a heat exchanger (coil) connected to a fan

Hot Water Steam Coils

Hot Water Steam Coils are heat exchangers used in HVAC systems to transfer heat from hot water or steam to air. They consist of tubes, usually made of copper or steel,

Rice Mill Heat Exchanger

Rice Mill Heat Exchanger is a device used to regulate and control the temperature during various stages of rice milling, such as drying, parboiling, and cooling.

Air Blast Oil Cooler

Air Blast Oil Cooler is a heat exchanger used to cool hydraulic oil, lubricating oil, or other fluids in industrial machinery and automotive applications.

Foundry Sand Cooler

Foundry Sand Cooler is a piece of equipment used in foundries to cool hot sand after it has been used in the casting process. The cooling process is essential to prepare the sand

Aluminum Finned Water Tube Coils

Aluminum Finned Water Tube Coils are heat exchangers used in HVAC systems to transfer heat between air and water. They consist of tubes, typically made of copper or another material